TBSTest - the Key to Build China's high-end INTEGRATED Circuit Test Equipment

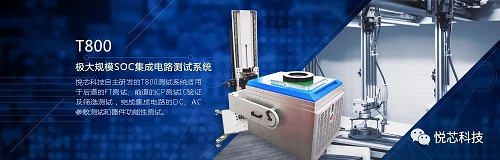

After two years of hard work by our Chinese and foreign R&D teams and the support of relevant parties, the first domestic very large-scale integrated circuit SOC test system was stably mass-produced on the customer's production line and various acceptance projects were successfully completed.

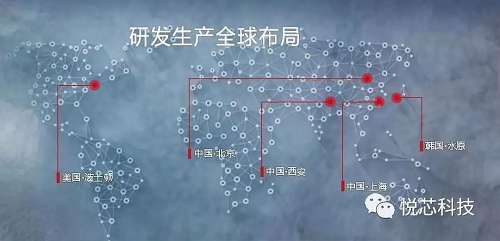

During this period, TBSTest has successively broken through several core test boards that are difficult to tackle and have high market coverage, such as high-density 800M digital I/O modules, high-speed high-precision analog signal test instruments, four-quadrant high-precision high-power power modules, etc. Technology; apply for more than 14 various related technology patents, including overseas technology invention patents; set up R&D centers in Xi’an, China, Suwon, South Korea, and Boston, USA, and cooperate with domestic universities to set up production, education, research and training bases; equipment through integrated circuit scale The mass production verification of the production line shows that the comprehensive technical capability of this type of SOC test system is close to the mainstream equipment parameters of the international leading enterprises, which greatly reduces the gap between domestic test equipment and international advanced test technology.

Describe the responsibility and responsibility of building the cornerstone of domestic high-end equipment

Integrated circuit chips are the core cornerstone of the information age. Integrated circuit testing technology represents the highest level of ultra-precision manufacturing in the world today. The integrated circuit industry has become a strategic industry that affects the security and comprehensive competitiveness of society, economy and national defense.

However, due to the integration of capital-intensive, technology-intensive, talent-intensive and other characteristics of the integrated circuit industry, my country’s integrated circuit industry has been constrained by various constraints in advanced manufacturing equipment, materials and processes for a long time. Related production test equipment mainly relies on imports, and foreign equipment suppliers basically monopolize the domestic high-end test equipment market.

"Major core technologies cannot be bought with money, and joint ventures cannot be obtained." Since the "T800" project was planned, the entrepreneurial team of TBSTest has been carrying forward the development of the "10 years of hard work, dedication, and persistence" for many years since the "T800" project was planned. Spirit, in accordance with the development idea of "overseas layout, domestic, partial complete sets, and international operation", it has overcome the key technology of very large-scale integrated circuit test equipment for the key equipment of integrated circuit manufacturing, and solved the restriction of the independent controllability of my country’s high-performance integrated circuit manufacturing equipment. The "stuck neck" problem of development supports the rapid development of VLSI and emerging electronic component industries, and expresses the responsibilities and responsibilities of the major powers of the country.

Break the monopoly and forge domestic brands of high-end test equipment for very large-scale integrated circuits

TBSTest is constantly making breakthroughs in key technologies. As of June 2018, it has applied for 14 technical patents (including overseas invention patents). It has realized the serialization of product design models and used them in the domestic related chip testing production line... This is the responsibility of the company's R&D department. Part of the results achieved by the project.

Very large scale integrated circuit test system is the core equipment essential for the upgrade and development of the integrated circuit industry manufacturing process-mainly to solve complex chip design verification, production testing and high-end imported equipment replacement. As the only domestic ATE supplier that has established an overseas R&D center. We will continue to invest in future new technology research and development plans, and continue to maintain the leading position of domestic high-end test equipment technology.

The company was registered and established in Beijing in February 2017, focusing on R&D, production, and sales of very large-scale integrated circuit chip test equipment (ATE). The company’s high-end SOC test equipment with completely independent intellectual property rights has filled China’s domestic high-end SOC Blank of test equipment. Provide high-performance, high-reliability, and customizable integrated circuit test solutions for domestic and foreign enterprise users such as integrated circuit design, production, packaging and testing, and scientific research institutes, universities and colleges.

The company has established R&D and technical service branches in Shanghai, Xi'an, South Korea, the United States, etc., and is striving to become a leading enterprise in China's high-end integrated circuit test equipment, an excellent domestic equipment solution provider and service provider.

"Accumulated as a tool, domestic high-end equipment is gradually building a complete supply system and forming a platform-based production capacity." The extremely large-scale integrated circuit test system independently developed by TBSTest broke the monopoly of the high-end market by foreign suppliers. A high-end domestic ATE brand.

Responsibility calls for responsibility, mission leads the future

Nowadays, the SOC integrated circuit ATE equipment developed by the company has reached the leading domestic and international advanced level; and plans to cooperate with industry leaders to build an integrated circuit advanced test process verification line with independent research and development equipment, in order to continue to improve domestic high-end integrated circuit test equipment The stability and reliability provide a good platform.

At present, the verification line has three major functions: one is to verify the equipment and process, and to verify the stability, reliability, and adaptability of the mass production environment for the whole series of equipment on the verification line; the second is to verify the mass production of ATE equipment, Enhance the ability to deliver equipment in batches; the third is to strengthen the ability of equipment to partially line up and accumulate experience for providing overall solutions.

As a new force in the field of high-end integrated circuit equipment, TBSTest will adhere to the concept of "Born for China and Test for the World", and strive to build a "big power" of high-end integrated circuit test equipment, and build the cornerstone of chip manufacturing. In the future, focusing on overcoming the key technologies of core equipment for IC testing, the company will continue to work hard with the two-wheel drive of technological innovation and market introduction. Focusing on related industries supported by high-end equipment and equipment industries, we will focus on improving the level of industrialization, through internal integration and external links, and gathering resources to build new overseas R&D centers and training bases; at the same time, we will cultivate the development and standardization of intelligent manufacturing electronics sub-industry The ability of smart equipment manufacturing and smart manufacturing system solutions has become one of the mainstream smart manufacturing backbone enterprises and smart manufacturing system solution providers in China.

For more news, please pay attention to our WeChat public account: